The major priority of the environmental policy of the FNHPP is to ensure the environmental safety and to reduce the environmental impact in the region.

The Chukotka Autonomous District with its distinct populated localities and industrial facilities features a great number of stand-alone diesel stations, and outdated Chaun TPP is located in the center of Pevek town. As the network infrastructure develops, the FNHPP will be able to replace the capacities of Bilibino NPP, the municipal TPP, and the small-scale power facilities thus relieving the region from the excess pollution.

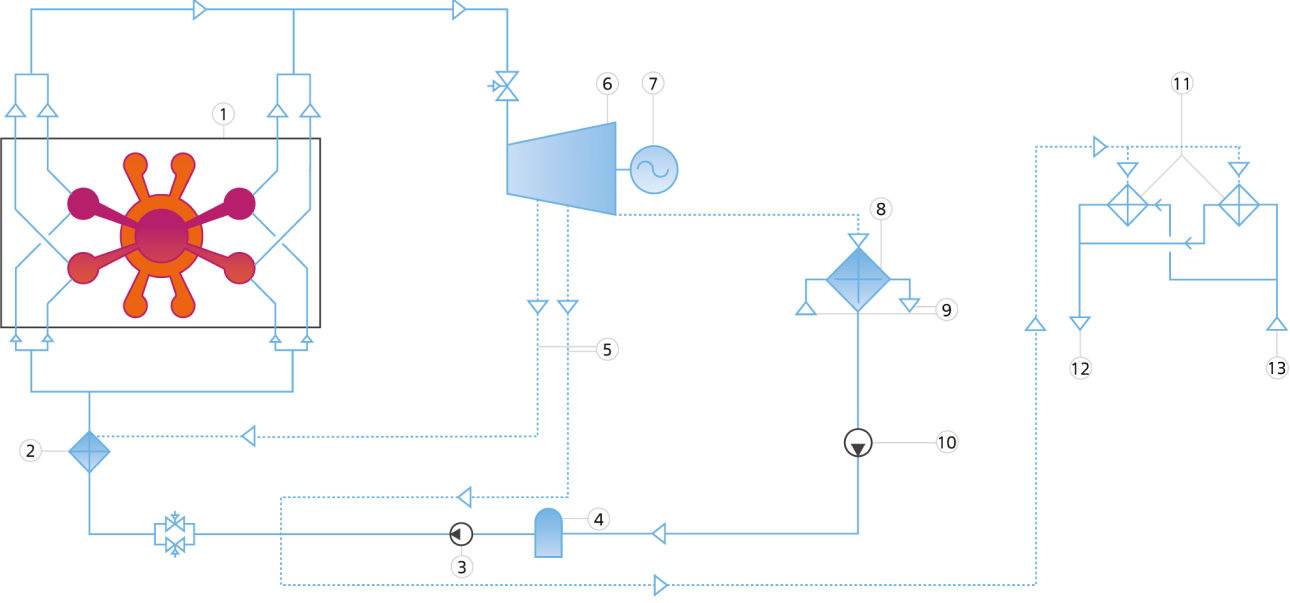

At the same time, all nuclear fuel and radioactive materials handling systems of the FNHPP are placed exclusively inside the FPU including reactor core refueling and storage of the spent fuel.

All operations with ionization radiation are also carried out only aboard. No radioactive waste is discharged to the overboard space.

The water heating system for the heat generation is executed through an intermediate circuit which prevents from a possible contamination of water with radioactive substances.

In this way, the radiation impact of the FNHPP on the population and the environment under normal operation or in any emergency situations does not exceed the natural radiation background level.

Continuous radiation monitoring is carried out in the sanitary protection zone around the floating nuclear heat power plant.